In today’s rapidly evolving manufacturing industry, LSR (Liquid Silicone Rubber) mold design has emerged as a cutting-edge technology that is revolutionizing the way products are customized for different markets. With its unique properties and versatility, lsr mold design offers endless possibilities for creating high-quality, durable, and precise components.

The Advantages of LSR Mold Design

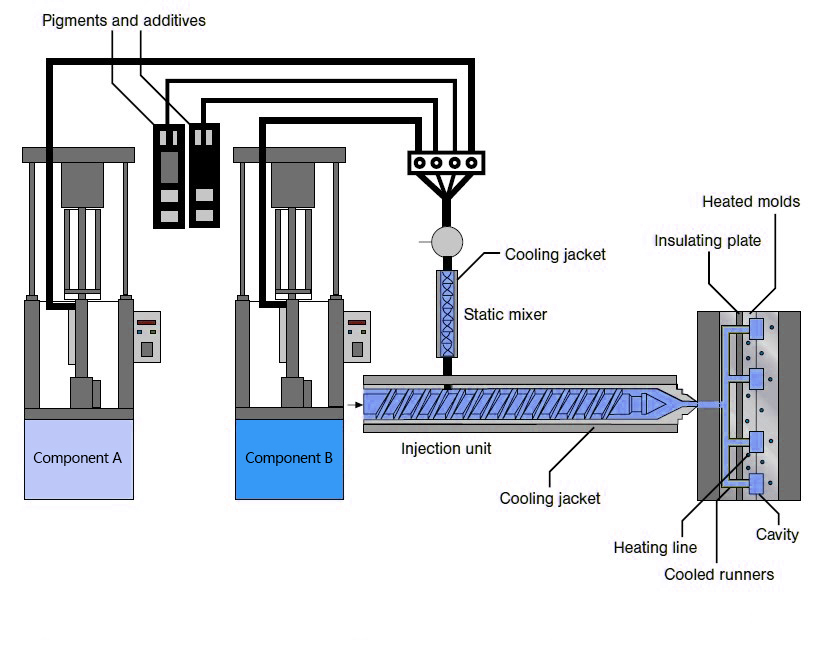

LSR mold design allows manufacturers to create complex shapes and intricate details with ease. The liquid silicone rubber material flows smoothly into every corner of the mold cavity, ensuring consistent part quality and minimizing defects. This level of precision is crucial in industries such as medical devices, automotive parts, and consumer electronics where reliability is paramount.

Furthermore, LSR molds can be designed to accommodate overmolding or insert molding processes seamlessly. This enables the integration of multiple materials or components into a single product without compromising structural integrity or functionality.

JVTECH: Pioneering Innovation in LSR Mold Design

One company at the forefront of LSR mold design innovation is JVTECH. With years of experience and expertise in this field, JVTECH has developed state-of-the-art technologies that push the boundaries of what is possible with liquid silicone rubber molding.

By leveraging advanced computer-aided engineering software and simulation tools, JVTECH engineers can optimize every aspect of the mold design process – from material selection to cooling channel layout – resulting in faster production cycles and improved overall efficiency.

The Rise of Smart Advanced Manufacturing

In addition to its advancements in LSR mold design, JVTECH also embraces smart advanced manufacturing techniques. By integrating automation systems and data-driven analytics into their production processes, they have achieved higher productivity levels while maintaining exceptional quality standards.

Smart advanced manufacturing allows for real-time monitoring of production parameters, enabling immediate adjustments to optimize efficiency and reduce waste. This level of control ensures consistent product quality while minimizing the environmental impact associated with traditional manufacturing methods.

In Conclusion

LSR mold design has revolutionized customization in the manufacturing industry. With its ability to create intricate shapes, integrate multiple materials, and ensure high-quality output, LSR molds have become indispensable in various sectors. Companies like JVTECH are leading the way by pushing the boundaries of what is possible with LSR mold design and embracing smart advanced manufacturing techniques. As technology continues to evolve, we can expect even more exciting developments in this field that will shape the future of customization in manufacturing.